Making Laminated Glass

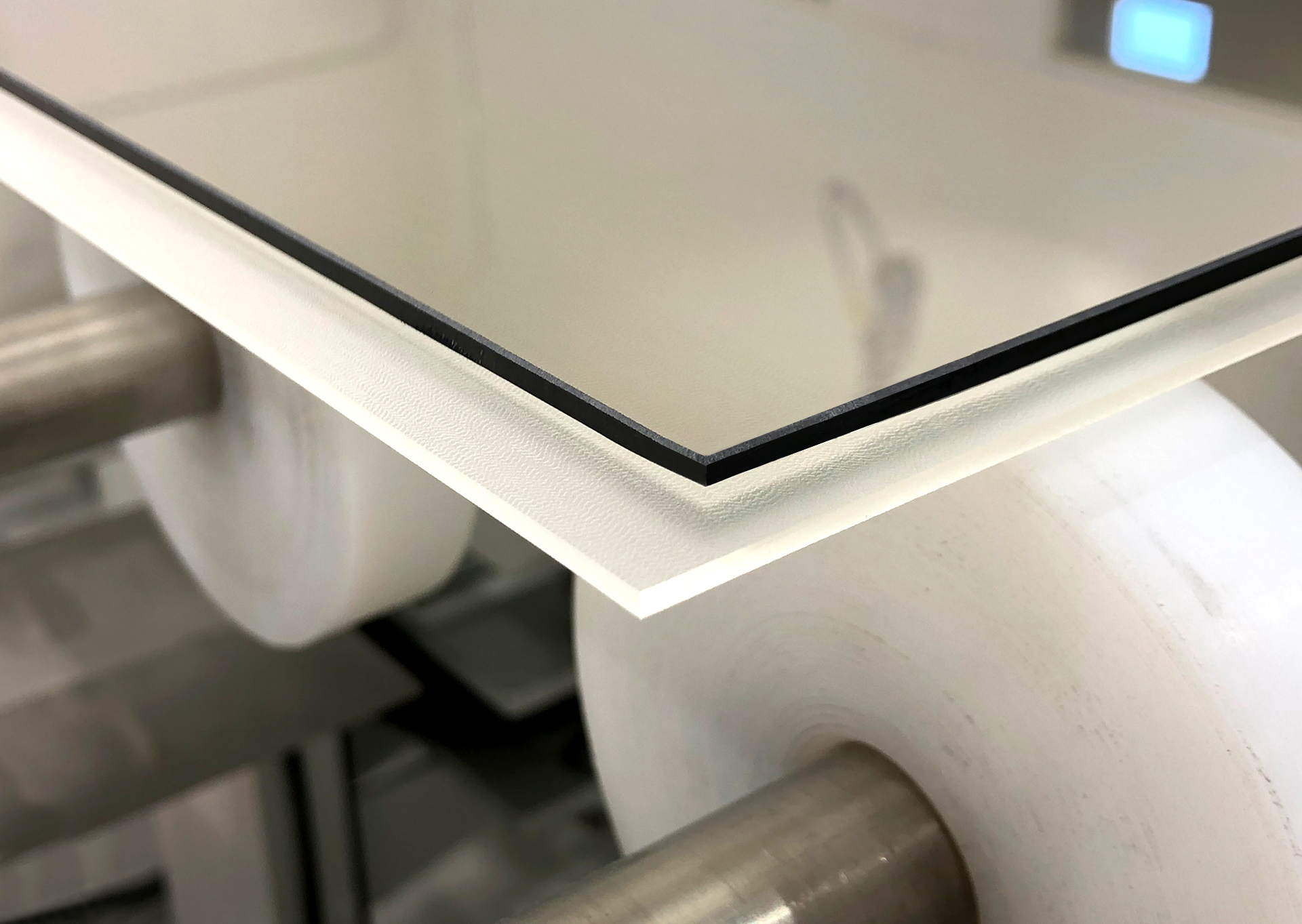

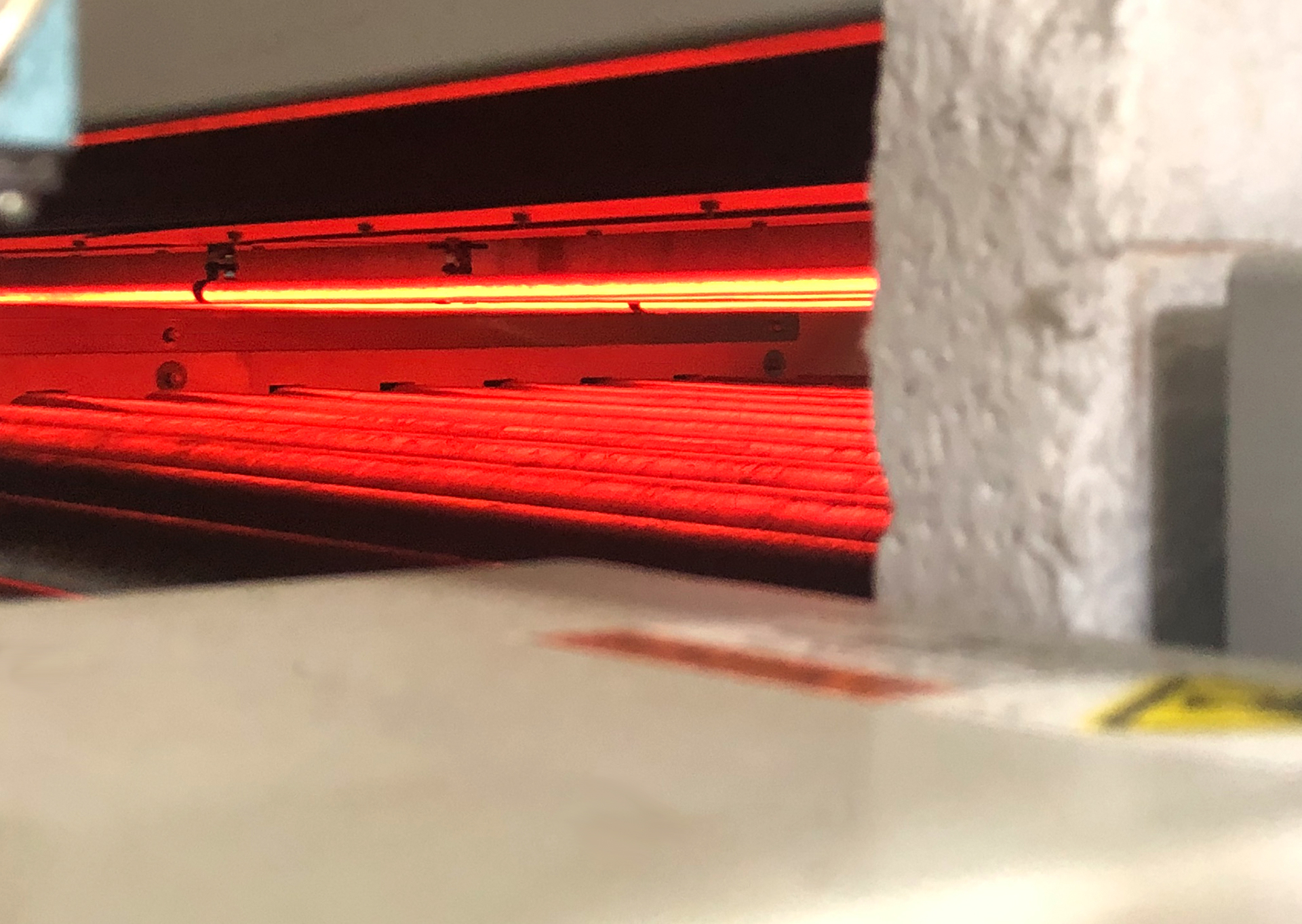

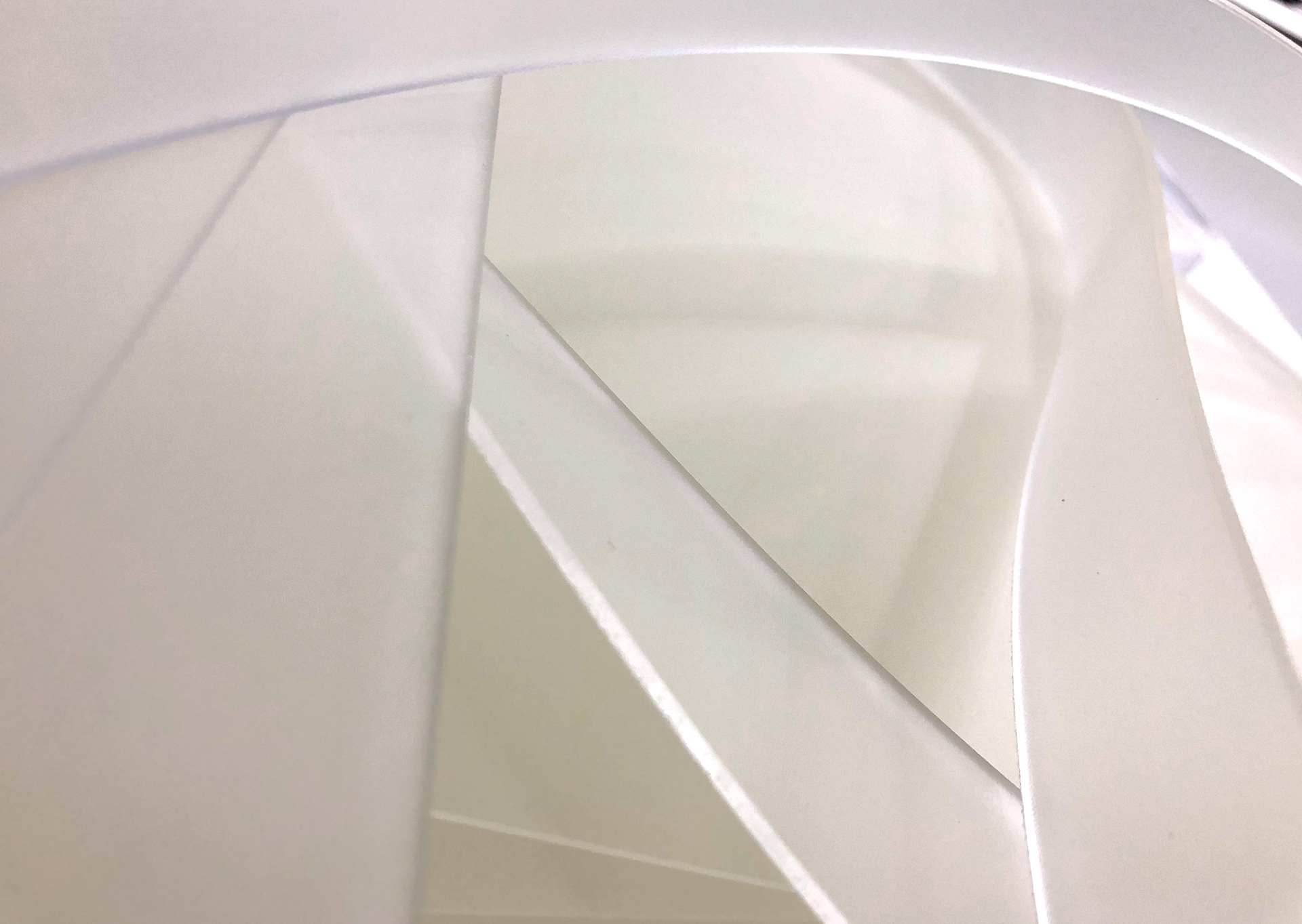

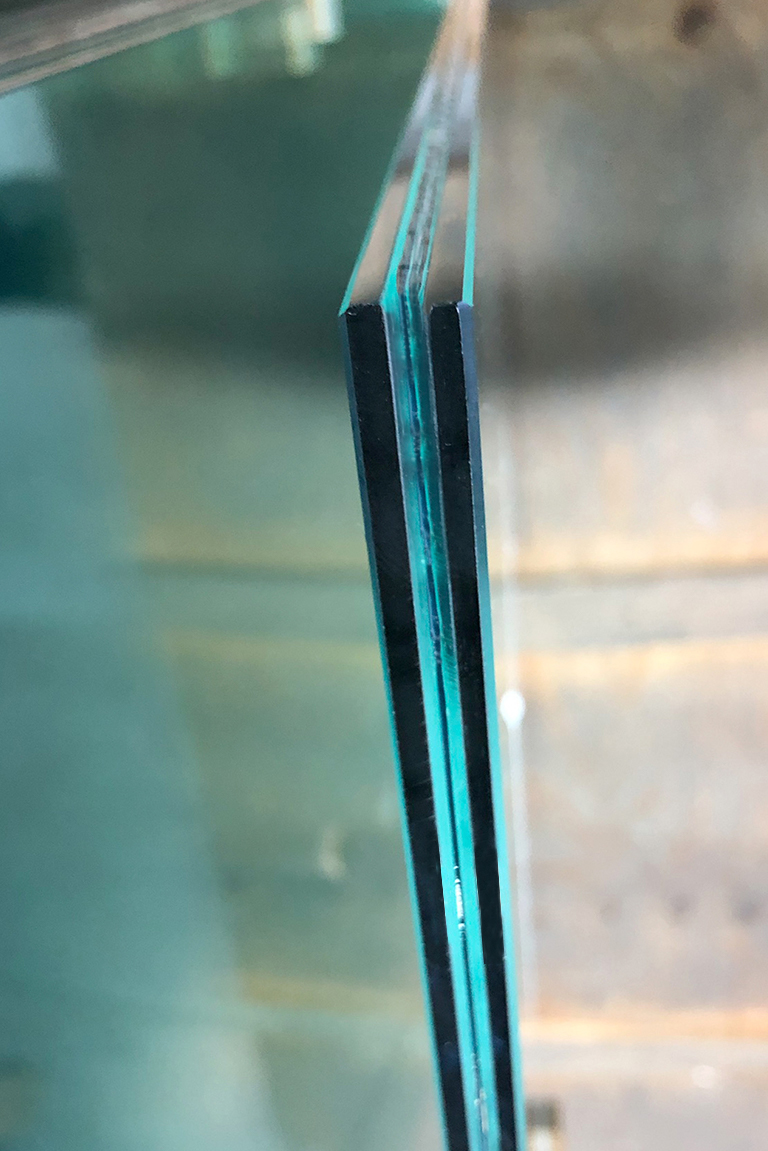

The process of making a laminated sheet of glass involves the binding of two pieces of heat-treated glass with an interlayer of polyvinyl butyral (PVB). The three pieces are layered and sealed by a series of pressure rollers and then heated, creating a mechanical bond of adhesive PVB and a chemical bond of oxygen – from which laminated glass gets its superior strength. Once the glass and PVB are bonded, the laminated glass is processed through a thorough wash of chemical water and sent to the autoclave for final hardening.